10 Things that made the P-51 Mustang fighter aircraft so outstanding

10: The Wing is the thing

By complete serendipity, the shaping of a laminar flow aerofoil (the cross section of the wing) is also very good for low drag at high speeds. The airflow over a wing accelerates even faster than the airspeed of the aircraft. At high enough aircraft speed, this local wing airflow will exceed the speed of sound. When this happens, drag increases to really high levels, really fast. To keep accelerating you need a lot more engine power.

The shaping of the Mustang wing lessened this airflow acceleration and allowed it to fly a little faster before this drag started its dramatic rise. In modern terminology, the Mustang had a great transonic wing. This effect was not fully understood in the early 1940s, but the science quickly followed up.

9: Low drag

In addition to the great wing design, the Mustang also had a remarkably low overall drag. The performance of the airplane is the summation of many little things and a close attention to detail. A close inspection of the Mustang will show its remarkable cleanliness. There are virtually no bumps, bulges, or inlet scoops anywhere on the plane. Most other planes of the era have a multitude of these to address various cooling or system details.

The landing gear is a great example. The main gear is fully enclosed by gear doors that fit well. The tailwheel is also retractable, unlike most aircraft of this era.

9: Low drag

Many sources will talk about the belly radiator system producing thrust by adding heat energy to the airflow. The test data shows that very little positive thrust is ever produced. However, in most high-speed conditions, the system is producing no net drag. This effect is important, as cooling drag at high power can be quite large. One last detail which results in low drag / increased thrust is optimal shaping of the engine exhaust stacks such that the exhaust airflow produces net positive thrust.

Test data shows that at high-speed cruise, this effect increases the net thrust by 20% or more. Low drag is not just about going fast. At any speed, lower drag means lower engine power, and lower fuel burn. This translates into an increase in aircraft range, which we will talk about next.

8: Goes the distance

Most fighters before the Mustang were not designed for significant range. Early in the war, fighters were used mostly as bomber interceptors and the air battles would take place near the fighter’s home airfield. The exception to this was fighters that were used in a ground attack role or for other missions such as photo-reconnaissance.

This was the initial design mission for the Mustang, and hence the aircraft was designed for greater range. As the Mustang was entering service in 1943, the US Army Air Force was executing a daylight bombing strategy and was starting to suffer often horrendously heavy bomber losses to enemy fighters.

8: Goes the distance

The USAAF began using the Mustang for long-range bomber escort. The Mustang’s low drag meant it could cruise with lower fuel burn than other contemporary fighters, and thus fly even further on the same fuel. Range was further increased with an additional fuselage tank and wing drop tanks (pictured). All of this gave the Mustang sufficient range to escort bombers round trip anywhere in Germany and even into Eastern Europe.

Several other long-range fighters like the P-38 and P-47 approached this capability. Although the Mustang has less manoeuvrability compared to some of the lighter fighters, like the Spitfire and Bf 109, it was superior to the P-38 and P-47 which were larger and heavier. The Mustang had the right balance.

7: Amazing Development Story

The Mustang has a great origin story. Prior to World War Two, North American Aviation – majority owned by General Motors – had developed a family of successful training aircraft. It desperately wanted to get into the lucrative fighter business. At the outbreak of the war, it had the early concepts for a fighter that incorporated much of the latest thinking in fighter optimization, including the radical new wing concept.

In early 1940, with the war starting to heat up, the British urgently wanted more fighters, and asked North American to build P-40s under license. North American, saw this as the chance to finish their original fighter design and have an immediate customer.

7: Amazing Development Story

The British took a gamble on the offer, and magic ensued. There are three common ingredients for a successful rapid aircraft development program: a team with the right expertise, the necessary funding and tools, and a challenging but realistic deadline. The North American team had all three and it was off to the races.

Based on the team’s prior research and design work, North American rolled out the prototype aircraft in an unprecedented three and a half months, and it flew a few months later. The team was able to work out the bugs and was delivering the initial aircraft to the British in October 1941, roughly 18 months after the contract was signed.

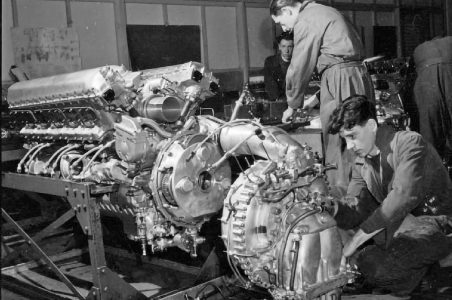

6: The Merlin

The Mustang and the Merlin were a match made in heaven. The 27-litre Rolls-Royce V12 Merlin is an engine that is loved by everyone, and for good reason. As the Mustang entered service, everyone was impressed with its solid performance, particularly at low altitudes. However, the original Allison engine had a single-speed, single-stage supercharger, and its power output dropped off quickly above 15,000 feet.

The most recently upgraded Merlin engine had a two-speed, two-stage supercharger that could shift gears and continue producing high levels of power through much higher altitudes.

6: The Merlin

Both the British and Americans started speculating on what the aircraft could do with the Merlin engine, and teams in both countries started projects to retrofit a Mustang with the engine. The British were slightly ahead, and their prototype flew a month before the Americans in October of 1942.

Both teams quickly realized it was the right combination, with high-altitude performance that exceeded any other fighter of the day. A vast majority of the Mustangs built used the Merlin engine, and its amazing success as a high-altitude bomber escort is because of this engine pairing. The Merlin was of course also a central part of the success of the Spitfire fighter, twin-engined Mosquito, and Lancaster heavy bomber. Most of the Merlins used in the Mustang were license-produced by car giant Packard in Detroit.

5: Allison

I don’t know the best comparison for the Allison V-1710 V12 engine, but maybe Cinderella? It certainly gets overshadowed by its boosted step-sister, the Merlin. The base engines are remarkably similar, with the later Merlin supercharger being the primary difference. And the Merlin did have a world-class supercharger design that the Allison lacked. However, the benefits of the Merlin supercharger are best at higher altitudes.

For any missions where low altitude was required, the Allison was a worthy contender. In fact, at lower altitudes, the Allison was slightly superior, due to the pressure mapping of the supercharger. For missions like ground attack the Allison was a nearly perfect engine and the aircraft operated exceedingly well in that role.

5: Allison

The General Motors-built Allison probably doesn’t get proper credit because the P-47 entered service soon after the Mustang and, with more armament, it was an even better ground attack aircraft. (The-P-47 was also an effective high-altitude aircraft with its unique engine/turbocharger installation.)

Due to the urgent need for long-range, high-altitude fighters, most Mustang production transitioned over to the Merlin-powered model which quickly eclipsed the Allison-powered Mustang. And that is a shame. I am a fan of both aircraft, for different reasons, and I wish the Allison got a little more love.

4: Bubble hood

The Mustang was one of the first aircraft to sport a fully unobstructed bubble canopy. This innovation came to reality mid-war as polymer plastic material science matured. One of the first iterations of this technology pioneered on the Spitfire, was called the “Malcolm hood.”

This was a hybrid solution that replaced the centre canopy section with a slight bubble Perspex canopy that contained no obstructions. This gave better visibility both laterally and vertically. But since the basic airframe was not modified, the aft view still suffered. This Malcolm canopy was retrofitted to B and C model Mustangs soon after the Spitfire.

4: Bubble hood

Both aircraft were going through a rapid evolutionary cycle and the next version of each aircraft (the Spitfire Mk VIII and the P-51D) took this idea a step further. In both cases, the canopy was enlarged, and the aft fuselage lowered to give an unobstructed view in nearly all directions. This idea did increase aircraft drag slightly. But that is a small trade for better pilot situational awareness.

This canopy design became the norm for nearly all fighter aircraft that came afterwards and remains the standard today. The clean bubble canopy strongly contributed the P-51D’s “modern” look as compared to the razorback fuselage and glazed canopy design of previous fighters.

3. Easy to build

Often engineering marvels are the equivalent of a Swiss watch. They might exhibit extreme performance, but they give up practicality in the process. They are either prohibitively expensive, difficult to maintain, or they compromise useability to maximize their primary performance metric.

An example of this type of design philosophy would be a racing vehicle. They are typically hand-built in low volumes, expected to last for just a few races, and are expertly maintained, often by their creators. The Mustang is the opposite of this.

PHOTO: North American Aviation factory at Inglewood, California in 1942

3: Easy to build

As you would expect from the influence of the world’s largest automaker, the P-51 was designed for profitable mass production and operational effectiveness from the beginning. An example of this philosophy is the wing and the tail. Despite the Mustang arguably having the best performing wing of the war, it was also amongst the simplest. It had a trapezoidal planform with straight leading and trailing edges.

This not only is simple and cost-effective to build, but it contributes to the higher manufacturing accuracy needed to achieve its aerodynamic efficiency. Straight lines are easier to align when building tooling, especially in the 1940s without the use of modern laser projection and measurement tools. General Motors sold North American in 1948; today after various mergers the company is part of Boeing.

PHOTO: Assembling the P-51’s landing gear at the North American Aviation factory at Inglewood, California in 1942

2: Landing gear

There were several arrangements for main landing gear on fighters of this era. Most were conventional taildraggers, with a few tricycle exceptions like the P-38 and P-39. The primary design difference between the taildragger aircraft is the direction of gear retraction: inward, outward, or aft. Each layout has pros and cons.

Landing gear generates high loads and outward retracting gear connects to the wing inboard, where it is stronger. This offers weight savings and was used on the Spitfire and Me-109. This layout also has a compromise: it tends to make the gear width somewhat narrow, which can lead to stability issues when landing.

2: Landing gear

The Mustang had inward retracting gear which allows for a wider gear stance. If a pilot lands with a wing low, a wider stance gear has a better ability to correct the roll angle on touchdown, without over-turning. Additionally, a wider stance gear allows for higher turning forces on the ground before the aircraft pivots on the outer gear and drags a wingtip.

Spitfire pilots tended to cope well with its gear arrangement, probably due to superior training. However, more than 10% of all Bf 109s were lost in landing and take-off accidents. This landing gear likely has a strong influence on this statistic.

1: Conical lofting

This might be the most obscure detail that contributes to the Mustang’s greatness. As an aircraft designer though, it is one of my favourites. The Mustang was one of the first aircraft to use a geometric design process referred to as “Conic Lofting”.Before we get into why this matters, let’s start with some definitions. “Lofting” is the process of creating the external shape of the aircraft, and the “Loft” refers to this final shape.

The term loft comes from the shipbuilding industry where the shapes of ship hulls were drafted (often at full scale) in a loft above the shipyard. Early aircraft development borrowed much from shipbuilding, including this term. In more modern language, the loft represents the collection of external aircraft surfaces.

1: Conical lofting

“Conic” refers to a type of mathematically defined curve. A conic curve is generated by slicing a plane through a cone, hence the name. A circle and an ellipse are both conic curves, among others. The advantage of a conic curve is that it can be described with high mathematical precision, and it is guaranteed to be a smooth curve with no reversal of curvature (assuming it is built per the definition).

This type of lofting provides two related advantages. First, it tends to produce aircraft surfaces that are very smooth and continuous, and thus promotes low drag. Secondly, these surfaces tend to look really pleasing to the eye. If you look at a Mustang fuselage closely, you can see evidence of this. The forward cowling is an exceptionally well-designed shape in both cross section and the way the shapes flow from spinner to canopy. The aft fuselage between the canopy and tail is similar.

Conic lofting is a minor detail on a practical level, but it is one more feature that puts the Mustang on a different level. As a footnote, modern lofts are generated by computer aided design (CAD) programs and conic lofting is one of several techniques still implemented today.